High-power fiber laser technology is the mainstream development direction of future laser cutting generally recognized by colleagues in the industry. Whether from the perspective of market competition or user application, the growth rate of high-power fiber laser technology is stronger year by year. Before 2016, the laser high-power cutting market was occupied by 2KW-6KW. Today, 12KW, 15KW, and 20KW have become the new darlings of the laser cutting market, and even 30KW-40KW laser cutters have been launched. Why are high-power laser cutting machines so popular? What are the advantages of high-power fiber laser cutting technology compared to medium and low-power laser cutting?

Advantage 1: Cutting limit thickness greatly improved

Currently, high-power laser cutting machines can cut aluminum alloy plates up to 40mm thick and stainless steel plates up to 130mm thick. With the continuous upgrading of high-power laser cutting machine technology, the thickness of cutting materials will continue to increase, the price of processing thick plates will gradually decrease, and the application of high-power laser cutting machines in the field of thick plates will be accelerated.

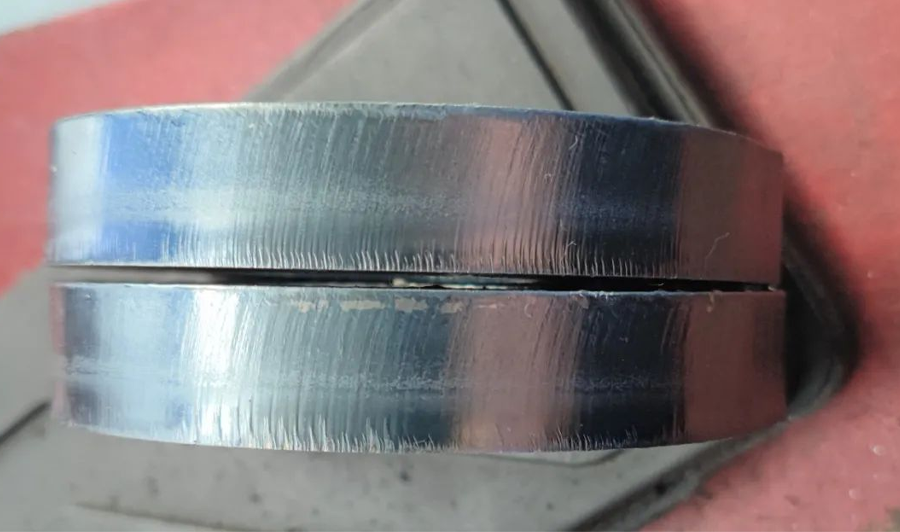

The cutting limit thickness of the 15kw fiber laser of Kepu Xinyu Laser reaches more than 75mm, and the cutting section effect is good.

Sample cutting by Kepu Xinyu 10,000-watt laser cutting machine

Compared with lower-power lasers, the cutting capacity has been improved significantly, which has greatly improved the processing range of laser cutting machines.

Advantage 2: Double the efficiency of cutting medium and thin plates

When selecting the power of laser cutting equipment, the cutting speed of different materials is a key factor to consider. The application of fiber laser cutting has significant advantages in the processing of medium and low-thickness plates. The increase in laser power can double the cutting speed. The increase in speed brings about an exponential increase in the economic benefits of fiber laser cutting machines.

Taking the common 20KW and 12KW on the market as examples, compare with the 6KW cutting speed:

It can be clearly seen that for carbon steel and stainless steel of common thickness, the cutting efficiency of 20KW and 12KW is significantly better than 6KW, and the cutting speed is increased by 50-320%. The smaller the material thickness, the less obvious the advantage is due to the excess power. The greater the thickness, the more obvious the advantage.

Advantage 3: Increased diversity of cutting processes

In addition to the advantage of cutting thicker and faster, with the increase of laser power, the laser cutting process can also play more tricks, such as the currently highly praised high-speed bright surface cutting technology.

High-power high-speed bright surface cutting technology (HHB, High power, High speed, Bright surface), that is, when the power is sufficient, use a small nozzle, small air pressure, and high-power laser to cut carbon steel plates of different thicknesses at high speed, so as to obtain a smooth cutting section and a smaller processing taper. The smooth cut surface is convenient for customers to process later; at the same time, the taper can basically be controlled below 0.2mm on both sides, which can better meet customer requirements in some high-precision processing industries.

Science and Technology Xinyu Laser Bright Surface Cutting Sample Display

To achieve fast and effective carbon steel bright surface cutting, three cutting conditions must be met:

· Small nozzle: double-layer nozzle, between 1.0-2.0mm.

· High power: The higher the power, the greater the limit thickness of the carbon steel bright surface that can be cut, and the efficiency will be significantly improved.

· Atmospheric pressure: Most of them are between 0.6-1.2Bar.

In actual operation, not only these conditions need to be met, but also professional debugging is required to achieve stable and consistent results.

Laser cutting, as a very ideal processing method in cutting processing, represents the development direction of modern metal processing technology. High-power laser cutting machines are currently conducting key technical research and development in the fields of high speed, high precision, large format, three-dimensional cutting and special material cutting, thereby promoting the technical development of high-power laser cutting to meet the growing market demand.